For which Angles \(\varphi\) are the Normal Stress \(\sigma_\xi\) and the Shear Stress \(\tau_{\xi\eta}\) Maximum?

Now we're going to find out when the normal stress and shear stress in a uniaxial stress state are at their greatest. So, buckle up, it's going to be exciting!

- It is stretched or compressed at one end..

- There are then stresses inside the bar.

- We can decompose these stresses into normal stresses and shear stresses.

To understand the solution, let's first dig up the formulas for normal stresses and shear stresses developed in the previous steps:

(1.4)

-

\(x\),\(y\)-system

$$ \begin{aligned} \tau_{\xi\eta} = -\dfrac{\sigma_x}{2}\bigl(\sin(2\varphi)\bigr) \end{aligned} $$

(1.5xy)

-

\(x\),\(z\)-sstem

$$ \begin{aligned} \tau_{\xi\eta} = \dfrac{\sigma_x}{2}\bigl(\sin(2\varphi)\bigr) \end{aligned} $$

(1.5xz)

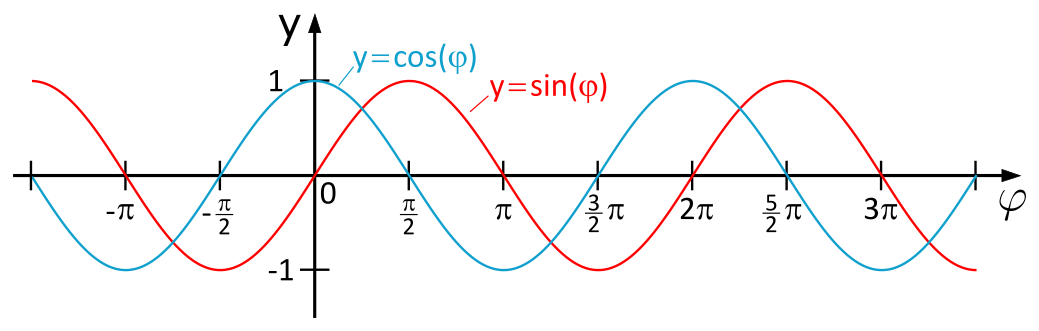

Interesting: The cutting angles \(\varphi\) at which the normal and shear stress are each maximum occur in the sine and cosine functions.

For our cutting angle \(\varphi\), only a small section of the image is actually interesting: the one between \(\varphi=0\) (perpendicular cut) and \(\varphi=90°\), which corresponds to \(\varphi=\frac{\pi}{2}\) (in radians).

- The sine curve reaches its minimum value of 0 at \(\varphi=0\) and its maximum value of 1 at \(\varphi=\frac{\pi}{2}\).

- The cosine curve reaches its minimum value of 0 at \(\varphi=\frac{\pi}{2}\) and its maximum value of 1 at \(\varphi=0\).

- In Eq.(1.4) we find the cosine - it is maximum when its argument is 0, i.e. for \(\varphi=0\).

- So the normal stress is greatest when you cut the bar perpendicularly.

- This is exactly perpendicular to the axis of the bar.

- In this case, the shear stress is zero.

- Can you imagine that? It's like the "strongest" cut.

- In Eqs. (1.5xy) and (1.5xz) we find the sine - it is maximum when its argument is \(\frac{\pi}{2}\).

- Watch out, it's a trap! Since the angle \(\varphi\) does not appear alone as the argument, but with the factor 2, in this case it is not \(\varphi=\frac{\pi}{2}\), but \(\varphi=\frac{\pi}{4}\)!

- So the shear stress is greatest when you cut the bar at an angle of 45 degrees to the axis of the bar.

- Remember: 45 degrees is the magic number!

- In this case, the normal stress is half as large as the maximum normal stress.

- Maximum normal stress

- Perpendicular cut to the rod axis

- Shear stress is zero

- Maximum shear stress

- Cutting angle of 45 degrees to the rod axis

- Normal stress is half as large as maximum normal stress

In the uniaxial stress state, the magnitude of the maximum normal stress \(\lvert \sigma_{max} \rvert = \lvert \sigma_{x} \rvert\) occurs in the perpendicular section, and the magnitude of the maximum shear stress \(\lvert \tau_{max} \rvert = \lvert \frac{\sigma_{x}}{2} \rvert\) occurs in the 45° section \(\bigl(\frac{\pi}{4}\bigr)\) to the applied load.

Normal and Shear Stress at an Arbitrary Section Angle

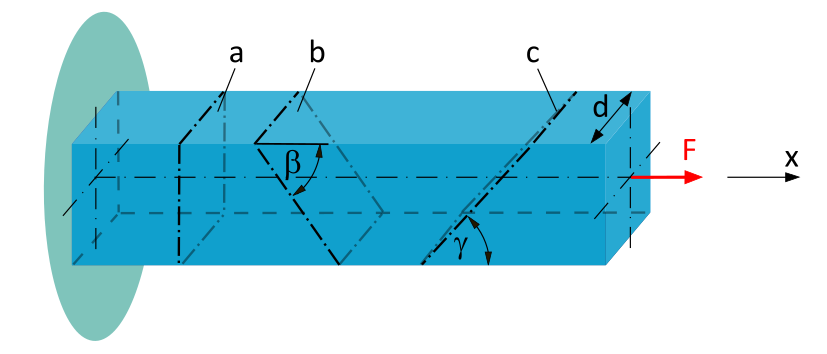

A clamped beam with a square cross-section (side length \(d=20~\mathrm{mm}\)) is subjected to a tensile force \(F=10~\mathrm{kN}\) along the beam axis.

Determine the average normal stress and the average shear stress...

- ...acting in cross-sectional plane a.

- ...acting in cross-sectional plane b (\(\beta = 50°\)).

- ...acting in cross-sectional plane c (\(\gamma = 40°\)).